Change: Interface PCB

Background

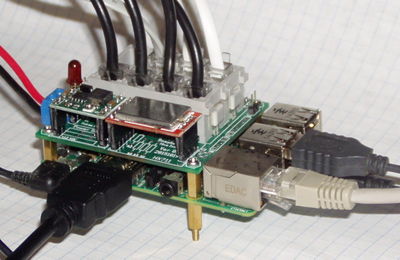

A Printed Circuit Board (PCB) has been designed and manufactured. The goals were to

- make it quicker and easier to build a system and to make it more reliable,

- to establish a relationship with a board house and

- to test the footprint of the RJ connectors and mating with the Pi

- to select a pcb layout package.

This is an interim solution - a step towards the goal of a complete turnkey system.

- All sensor plug in.

- 12 VDC power supply with battery voltage monitoring

Problems

- ADC is only one channel.

- No Real Time Clock (RTC).

- Board does not meet Pi HAT specification.

- Board is not general purpose but limited to our use.

Proposed change

Split this board in two, Board A and Board B.

- Board will we a general purpose interface board that meets the Pi HAT specifications and contains:

- at least one 4 channel ADC so each load cell will be individually measured instead of being summed.

- Real Time Clock with battery backup.

- Configuration ROM

- Board B will have all the connectors installed in a bulkhead configuration.