Difference between revisions of "Hardware: Frame Assembly"

(→Parts List) |

|||

| Line 5: | Line 5: | ||

==Parts List== | ==Parts List== | ||

| − | + | Part numbers, suppliers and prices are on the [[Media:Chesick scale costs.pdf|Parts List]]. | |

==Tools== | ==Tools== | ||

Revision as of 17:02, 7 December 2014

Contents

Goals, Features, and Flaws

For design goals, features and flaws, see the Frameless Scale Design

Parts List

Part numbers, suppliers and prices are on the Parts List.

Tools

- Tape Measure

- Pencil

- Layout or speed square

- Hacksaw

- Drill

- 1/4" drill bit

- Center Punch

- File

- 10 mm wrench

- 13 mm open end wrench

- 7/16" hollow punch

- Feeler Gauge

- Small straight blade jewelers screwdriver.

Optional tools:

- Metal cutting band saw or cut off saw

- Drill press

- Stationary disk sander

Fabricate Rails

Cut Strut

Cut the strut in 20" lengths. Three can be cut from 5' strut, six can be cut from 10 foot lengths. The rails may be slightly less than 20" after losing the width of the saw kerf.

- Mark the strut using a tape measure, If using a hack saw, transfer the marks around the strut using a layout square.

- Carefully cut the strut on the lines, trying to keep as straight and square as possible.

Transfer Layout

Method 1:

- Place a load cell on the top of the rail. It should be about 4 mm (1/4") from the end. NOTE: If it is more than 4 mm from the end you will not be able to tighten the lock nut on the foot and the end cap will not cover the closure strip.

- Using a transfer punch, mark the two 8 mm mounting holes.

- Repeat on the other end.

- Check the punch marks to make sure they are in a straight line.

- Punch the marks deeper using the center punch.

Drill and Debur

Drill the four 1/4 holes in each rail to mount the load cells. Use a file, deburring tool, or stationary disk sander to clean up the ends. They will be covered by the End Caps so they don't have to be perfect. Use a file or deburring tool to debur the holes.

Assemble Rails

Mount Load Cells

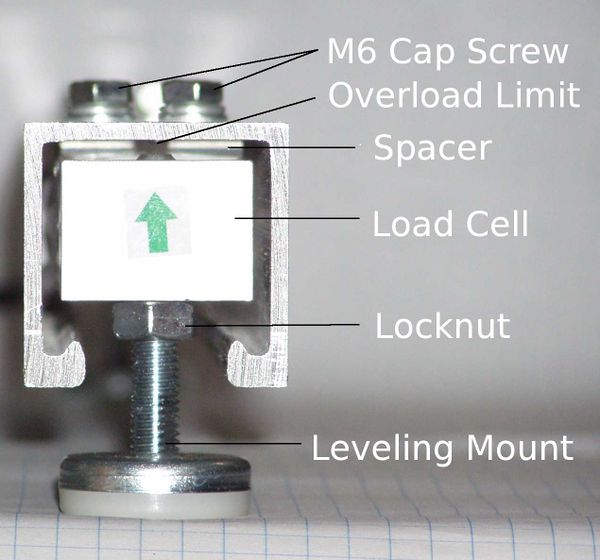

Turn a rail upside down with the open side up. Place a spacer over the holes. Carefully position the load cell over spacer. Align the holes without shifting the spacer.

NOTE: The green arrow on the end of the load cell should point down, toward the top of the rail.

Place a lock washer and flat washer on a M6x30mm bolt. While holding the load cell and spacer in place with one hand, start the bolt in one of the holes. Do the same for the other bolt. Make sure the load cell is centered in the strut and not touching the sides. Tighten the bolts.

Thread an 8 mm hex nut on each leveling foot.

Screw the leveling feet all the way into the load cells. The leveling foot should go all the way through the load cell, but not touch the strut.

Cut Closure Strips

Measure the distance between the leveling feet.

Using the hacksaw, cut the closure strip to fit between the leveling feet. If the strip is cut too long, a rat tailed file or rasp can be use to cut a semicircle in the ends. The closure strips should not contact the threaded portion of the leveling feet.

Punch End Caps

Set Overload Limits

Solder shield and terminal block connectors on HX711 board.

This is already done on the developer kits, This step is only necessary if you obtain parts independently.

Solder shield and connectors on HX711 board.

Assemble Electronics

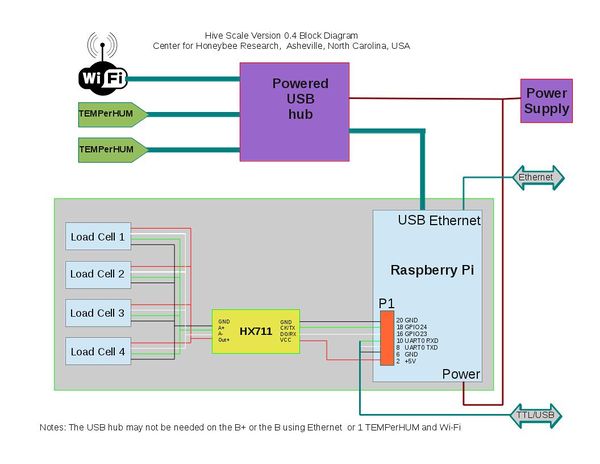

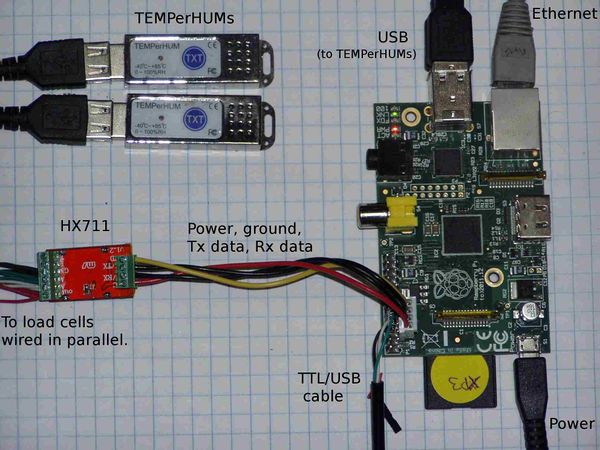

The electrical connections are made as shown on the block diagram.

Connect load cells.

- Each load cell has five wires:

- Red (V+)

- White (A+)

- Green (A-)

- Black (Ground)

- Black (Shield)

Do not cut or extend these wires for best performance. These load cells are a matched set.

The four load cells are connected in parallel (the four red wires are connected together, the four white wires are connected together, etc.)

Connect power and serial I/O cable to HX711 board.

Connect HX711 serial I/O cable to Pi.

Pins 2, 16, 18, 20 on H1 are used:

Pin 2 +5 Red Pin 16 White Pin 18 Green Pin 20 Ground Black

| H1 | Pi | HX711 | Color |

|---|---|---|---|

| H1-2 | +5 | Vcc | Red |

| H1-16 | GPIO28 | DO/RX | White` |

| H1-18 | GPIO30 | CK/TX | Green |

| H1-20 | Ground | GND | Black |

Connect USB/Serial Console cable to Pi

Pins 4, 6, 8, 10 on H1 are used:

| H1 | Pi | Color |

|---|---|---|

| H1-4 | +5 | Red |

| H1-6 | Ground | Black |

| H1-8 | GPIO28 | White` |

| H1-10 | GPIO30 | Green |

Connect Hub, WiFi, and TEMPerHUMs

Testing

If you have not installed the operating system and software on the SD card, load hivetool on the Pi now.

Powering the Pi

There are several ways the Pi, scale. and other sensors can be powered:

- With a Type B USB to Micro USB cable pluged into the power connector on the Pi.

- This is the preferred method as the pico fuse on the Pi board is used.

- The other end of the Micro USB cable can be plugged into a USB power supply like a cell phone charger, a powered USB hub, or a USB port on a computer.

- Through the USB console cable

- This is convient for testing but the pico fuse is bypassed.

- Backfeed through the Pi's USB port with a special USB Type B to Type B cable.

- The pico fuse is bypassed.

- The USB Type B to Type B cable is dangerous to have around. Do not use it to connect two powered devices, such as two laptops, together.

Note: It is important to only use one power source at a time. For example, do not power the Pi through the Micro USB power connector and through the USB console cable. The two power supplies may fight each other and burn up!

Mount in Enclosure

Several enclosures can be used.