Difference between revisions of "Frameless Scale"

(→Design Features) |

|||

| Line 16: | Line 16: | ||

*Load cells are mounted in metal strut readily available from electrical or industrial suppliers in aluminum. galvanized or painted steel. | *Load cells are mounted in metal strut readily available from electrical or industrial suppliers in aluminum. galvanized or painted steel. | ||

*Only straight cuts and drilled holes. | *Only straight cuts and drilled holes. | ||

| − | * | + | *All electrical connections are made with crimp plugs or terminal blocks. |

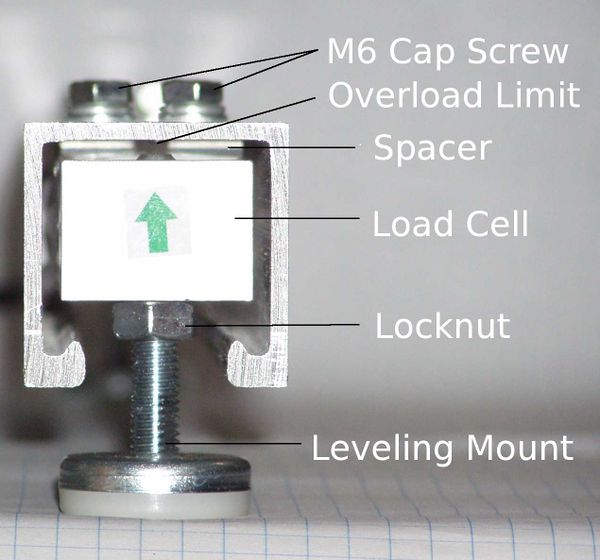

[[File:Chesick1.jpg|thumb|600px|Exploded parts diagram.]] | [[File:Chesick1.jpg|thumb|600px|Exploded parts diagram.]] | ||

Revision as of 01:29, 2 October 2014

Goals:

- Parts cost under $100 and are readily available.

- Low thermal drift and creep.

- Low power consumption.

- Automatically resumes operation after power failure.

- Can be built by 15 year old student (9th grader) using hand tools.

- No soldering.

- No lethal voltages.

Design Features

- No frame: no welding, no bending.

- Load cells are mounted in metal strut readily available from electrical or industrial suppliers in aluminum. galvanized or painted steel.

- Only straight cuts and drilled holes.

- All electrical connections are made with crimp plugs or terminal blocks.